Heat exchanger IC10 – IC10+ PROGRESS

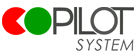

IC10 HEAT EXCHANGER has been developed to optimize production costs in modern poultry houses. It assumes most part of the ventilation during the first-stage in our farms, achieving huge reductions in heating fuel consumption and precise airflow from start.

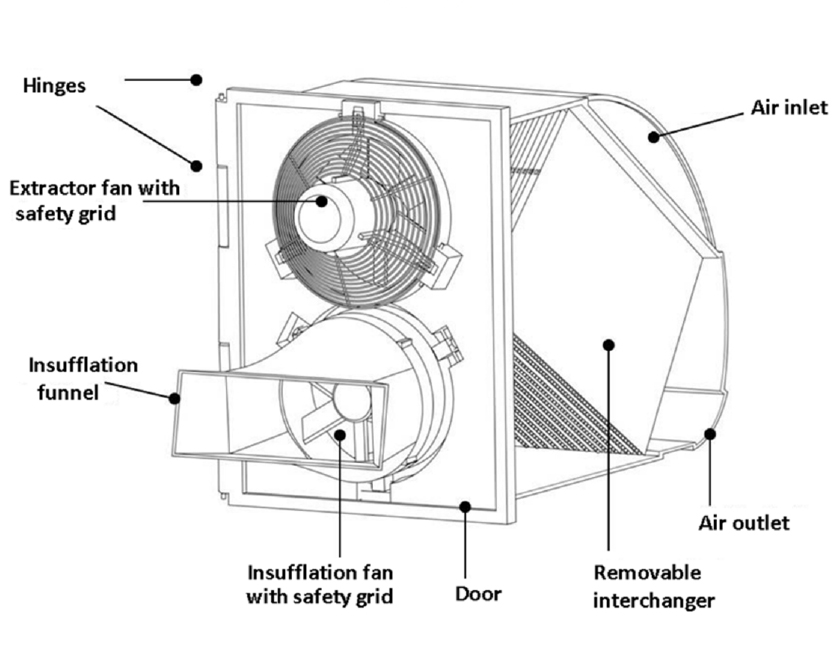

FEATURES

- Electrical data: 220V – 1A (IC10) – 2,2A (IC10+ PROGRESS).

- Quality hermetic gasket.

- Maximum heat exchange.

- Easy maintenance.

- Manual cleaning cycle or with programmer.

- Corrosion resistant polyethylene and robust materials.

- 2 available models: fan at 1.400 rpm/min (IC10) and fan at 2.800 rpm/min (IC10+ PROGRESS).

- Optional REC regulator for centralized management for IC10.

- Frequency inverter for IC10 + PROGRESS.

- Width 550 mm. – Height 730 mm.

- No drainage in the poultry house.

AIR EXTRACTION AND INTRODUCTION FEATURES

TECHNICAL DATA

| MODEL | IC10 | IC10+ PROGRESS |

EXCHANGE SURFACE | 77 m² | 77 m² |

REAL FLOW m³/h. – EXTRACTION (1) | 1.600 m³/h. | 2.500 m³/h. |

REAL FLOW m³/h. – INJECTION | 1.100 m³/h. | 2.500 m³/h. |

THERMAL PERFORMANCE (2) (%) | 78 % | 74 % |

MAXIMUM TREATED SURFACE (M²) | 250 – 300 m² | 250 – 300 m² |

ELECTRICAL CONSUMPTION (3) (W/h.) | 220 W. | 0 to 500 W. |

APPLICATIONS | Chicken, Turkey breeding, Piglets, Lambs. | Chicken, Turkeys, Ducks. |

(1) – Real Flow measured in compression chamber, with IC10 completely clean.

(2) – As information data only.

(3) – Depending on the flow rate – IC10 + PROGRESS with frequency inverter.

RANGE

- IC10 Model: Better energy efficiency, specially designed for houses with high temperatures (chicken, turkey breeding, Piglets, Lambs…) and short batches, where maximum savings are sought.

- IC10+ PROGRESS Model: It has a greater ventilation power. It works in progressive mode with the weight curve of the animals and their need per kilos. Without excessive speed at start, it manages minimum ventilation flows more efficiently than with air inlets. More savings in electricity consumption.

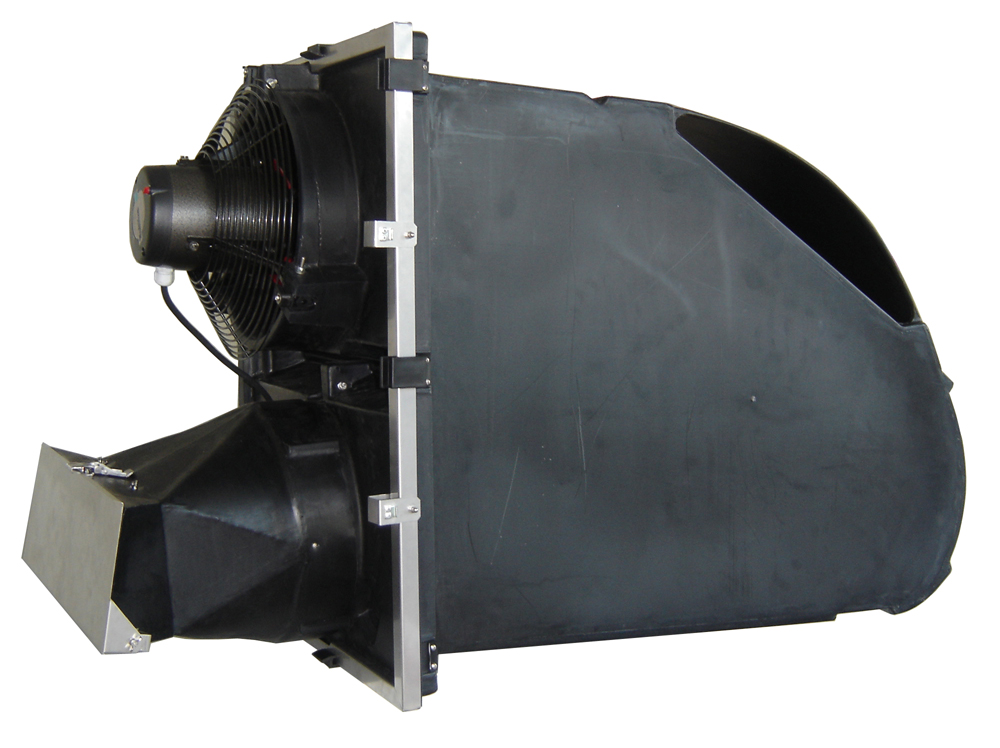

IC10+ PROGRESS

IC10 SCHEME